Steel Castings

As a key source in the steel casting industry, we value customer satisfaction and superior customer service. Our foundation is built on excellent customer care, the ability to supply an extensive range of steel casting products with competitive pricing, short lead times and maintaining an experienced staff to ensure quality. We remain a leader in our field by maintaining superior service standards in the industry. Our prime focus remains developing and retaining long-term relationships with our customers, partners and suppliers. Success in the steel casting industry comes from being highly technical and highly involved with projects from start to finish and maintaining excellent communication with our customers during the steel casting process. Our dedicated team of professionals will work with clients to help develop a quality steel casting by determining the customers goals and suggesting ideas to help make a better casting without sacrificing quality or performance.

Our steel castings serve many different industries, including steel castings for the military, mining & construction. Each steel casting is visually inspected by MSS-SP-55 and ASTM A802 standards.

At Sawbrook Steel, quality is our number one priority. We are ISO Certified and have implemented the BLIS Management Process Control System.

Our facility has also installed SolidWorks and Solid Cast software. We take great pride in being a one-stop destination for finished parts. Less red tape, more quickly completed projects. We strive to ensure that our customer service department is as responsive as they are efficient to make this happen.

See below for details on the various services we provide:

Pattern Design & Development

Our pattern shop has two pattern engineers with 30+ years experience building patterns, and capabilities for in-house patterns. We use SolidWorks and Solid Cast solidification software and 3D modeling for all jobs.

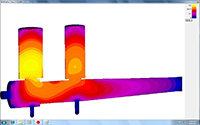

Solidification Modeling

Sawbrook Steel offers solidification modeling if requested. Solidification Modeling aids in pattern building, improves customer confidence, reduces scrap and prevents mistakes before they happen.

Pattern Storage

Patterns are stored in two separate buildings. Both buildings are covered, have emergency sprinkler systems and are secured by 24 hour surveillance. Our computerized information system keeps track of pattern locations which allows for fast and easy locating of tooling.

Cores & Molds

We take great care of our cores and molds to assure the best surface finish and dimensional control.

Molds we produce: Green Sand and No Bake

Cores We Produce: Oil Sand, Green Sand, CO2, No Bake, and Shell.

Melting & Heat Treating

We do our own melting and heat-treating. Our electric arc furnace produces a wide range of steels with heat size ranges between 7,500 and 15,000 pounds. Our in-house heat treatment facility has three car-bottom batch furnaces and a 9,000 gallon water quench tank.

Our methods of heat treatments: Stress Relief, Annealing Normalizing, Quench & Tempering, and Normalize & Temper.

Finishing & Welding

After a casting is shaken out of a mold it is sent to our finishing department where we will clean the casting of all excess sand and get the casting in top shape for our customer. Our surface finishing capabilities include arc air torch cutting, blasting, grinding, pressing and welding.

Other Services

Other services we offer include Blasting, Painting, Non-destructive testing, X-Ray & Ultrasonic Examination and Magnetic Particle Examination

Sawbrook Steel Resources and Company Information

See the pages below for information about our foundry, services, certifications and more.

You can also download our general brochure.

Services & Facility

Steel casting foundry information and list of industries served.

Sawbrook Forms

Virtual booklet of all of our forms, as well as downloadable individual PDF files of each.

Materials Poured

List of materials poured at Sawbrook Steel Casting.

Steel 101

New to castings? See how steel castings are made, and why they are so important.